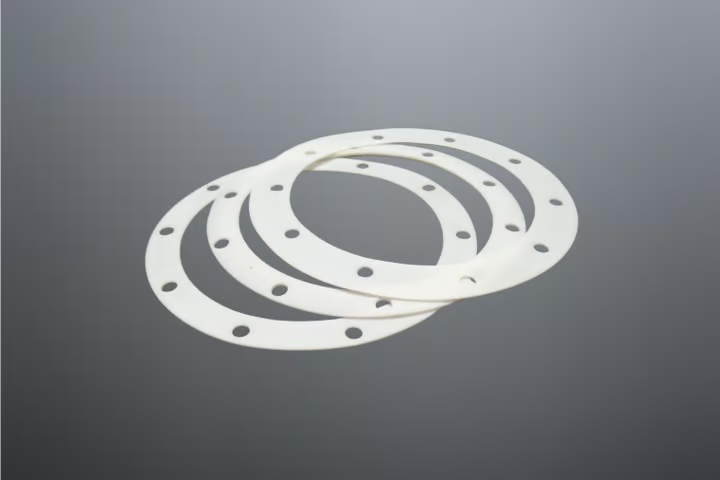

Expanded PTFE (Polytetrafluoroethylene) gaskets are commonly used for sealing in various industries.

Our Expanded PTFE Gasket is designed specifically for highly challenging usage in highly challenging industries. Our product is made by high-quality PTFE to offer high-quality products.

Key Properties of Expanded PTFE Gasket

- Chemical resistance: Withstands harsh chemicals and corrosive fluids.

- Soft and flexible: Easily conforms to irregular surfaces.

- Non-wetting: Repels liquids, preventing contamination.

- Wide temperature range: Works from -200°C to 260°C.

- Low friction: Ensures a smooth seal without sticking.

Types of Expanded PTFE

- Standard Gaskets: Standard Gaskets are used for normal duties such as sealing pipes and other equipment.

- Custom Gaskets: Custom gaskets are designed to fit special shapes and sizes of equipment which are well suited for the peculiar equipment.

- Expanded PTFE Tape: This is like a strip of tape that covers a small or irregular contour of the surface that could not fit with a regular gasket.

Applications of Expanded PTFE Gasket

- Chemical Industry: Expanded PTFE Gasket is used in the prevention of leaking pipes and mechanical systems. They deal with aggressive state chemicals.

- Food and Drink: Expanded PTFE Gasket is excellent in sealing equipment used in food factories to prevent contact with contaminants.

- Pharmaceuticals: Expanded PTFE Gasket is crucial in medicine-making machines. They help keep everything clean and hygienic (free of germs).

- Oil and Gas: Expanded PTFE Gasket can withstand high pressure and high temperatures in the oil pipe and tanks.

- Water Treatment: Expanded PTFE Gasket also plug cracks in systems used for cleaning and filtering water so as to avoid the formation of rust on the utilities.

Mechanical Properties

| Property | Value | Standard (Norm) | Description |

| Tensile Strength | 20-25 MPa | ASTM D638 | Withstands pulling forces without breaking. |

| Elongation at Break | 200-300% | ASTM D638 | Flexibility before it breaks. |

| Compressive Strength | 6-9 MPa | ASTM D695 | Resists compressive forces applied during sealing. |

| Hardness (Shore D) | 50-60 | ASTM D2240 | Resistance to surface indentation and wear. |

| Density | 2.2-2.4 g/cm³ | ASTM D792 | Weight per unit volume, affects material durability. |

Thermal Properties

| Property | Value | Standard (Norm) | Description |

| Thermal Conductivity | 0.24 W/m·K | ASTM C177 | Rate of heat transfer through the material. |

| Melting Temperature | 327°C | ASTM D3418 | The temperature at which expanded PTFE begins to melt. |

| Continuous Service Temp | -200 to 260°C | ASTM D3418 | Range in which the material functions effectively. |

Electrical Properties

| Property | Value | Standard (Norm) | Description |

| Dielectric Constant | 2.0-2.1 | ASTM D150 | Measures electrical insulating ability. |

| Dielectric Strength | 70-80 kV/mm | ASTM D149 | Capacity to withstand electrical breakdown. |

| Surface Resistivity | 10^18 Ω | ASTM D257 | Resistance to current leakage along the surface. |

Other Properties

| Property | Value | Standard (Norm) | Description |

| Water Absorption | <0.01% | ASTM D570 | Ability to repel moisture and maintain its seal. |

| Coefficient of Friction | 0.04-0.08 | ASTM D1894 | Low friction between gasket and surface for smooth fitting. |

Advantages of Expanded PTFE Gasket

- Non-corrosive: Expanded PTFE Gasket cannot degrade by rust, chemicals, or even corrode easily thus making them durable. This makes them highly durable, especially in chemically aggressive environments as illustrated in the sections above.

- Minimal Maintenance: Sealing gaskets produced from expanded PTFE are durable and durable and essentially maintenance-free. This helps in decreasing the rate of replacement hence cutting the operational costs in the long run.

- Non-contaminating: Their non-stick and chemically inert characteristic makes them suitable to be used in food packaging, pharmaceuticals, and places that require cleanliness.

- Works in Extreme Temperatures: The same gaskets when used at low temperatures and when exposed to high temperatures then good gaskets in extreme temperatures are the expanded PTFE gaskets. They offer good sealing in temperature conditions varying from -200 degrees Celsius to 260 degrees Celsius.

- Cost-Effective: Expanded PTFE gaskets have high durability, mean that there is less time lost on replacement. Therefore, less cost to the company than other gasket materials that can be used in a broad range of industries.

Reviews

There are no reviews yet.