Carbon Filled PTFE was developed to improve the standard or pure PTFE products. It has better mechanical strength. Best Carbon Filled PTFE is a composite material that holds the properties of PTFE and carbon filler. It is an advanced version of PTFE products. Using carbon filler with the PTFE, it is uniformly distributed to the PTFE and provides an increased wear resistance, higher thermal conductivity, and improved load-bearing capabilities. Carbon Filled PTFE products are a perfect choice for applications which require heavy loads, high temperatures and harsh chemical environments.

For high-grade Best Carbon Filled PTFE, Goa Polymer is well Known. We ensure the quality of the products. Our Carbon-Filled PTFE products offer superior wear resistance, electrical conductivity, and mechanical strength. Get all kinds of Carbon PTFE products like PTFE seals, PTFE gaskets, PTFE sheets and many more. Goa Polymer is the leading Carbon Filled PTFE manufacturer in India to meet the most demanding requirements.

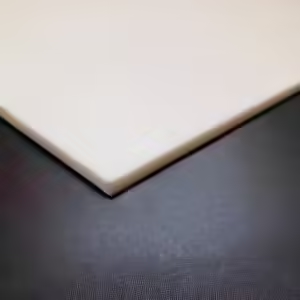

Best Carbon-Filled PTFE With 25-35% Carbon Filler

If you are looking for Carbon Filled PTFE products or manufacturer or supplier, then you are in the right place. Goa Polymer uses 25-35% carbon filler to manufacture the Carbon PTFE products for better quality. Carbon-Filled PTFE with a 25-35% carbon filter is the best choice for industrial application. It holds the unique properties of PTFE (Polytetrafluoroethylene) with the benefits of carbon. Containing 25-35% carbon, it enhances the wear resistance, high friction environment, excellent thermal conductivity, superior chemical resistance and better mechanical strength. Our products are durable, reliable and versatile in performance.

Properties of High Quality Carbon Filled PTFE

Carbon Filled PTFE products are made by adding carbon fillers to PTFE (Polytetrafluoroethylene). The combination of both materials gives enhanced properties and enhances the performance of pure PTFE. It is ideal to use for industrial applications. Here are the properties of Carbon PTFE-

- Wear Resistance: This enhanced PTFE has enhanced wear resistance properties. Using 25-35% carbon filler increases the mechanical wear and the material’s ability to fight in all cases. This property is valuable in applications like seals, bearings, etc. When there is high wear resistance in the product, it is a sign of longer service life and maintenance costs.

- Thermal Conductivity: This PTFE has enhanced thermal conductivity. Pure PTFE has an excellent insulator, but the Carbon-Filled PTFE can hold more heat. Using this is ideal for electronic and electrical insulation. Such products can prevent overheating and enhance the overall reliability of the system.

- Electrical Conductivity: They have enhanced electrical conductivity. This property is not found in the pure PTFE. Carbon has the properties of conductive. Using carbon filler with the PTFE makes the PTFE product conductive resistance. Such products are ideal to use for electronic applications.

- Mechanical Strength: They have higher mechanical strength as compared to unfilled or pure PTFE. Having high mechanical strength in the application makes it rigid and load-capable. It is highly used in high-pressure and high-load applications.

- Chemical Resistance: Using carbon filler, PTFE still holds excellent chemical resistance properties. Being chemical resistant, it is used in a wide range of chemicals like acids, bases and solvents. It is perfect for the chemical processing industry.

- Low Friction and Non-Stick Properties: Carbon-Filled PTFE product maintains the low friction and non-stick properties of PTFE. Pure PTFE also has these properties. However, Carbon rich PTFE has a low coefficient of friction. Hence, it is ideal for smooth and lubricated motion applications.

- Dimensional Stability: Carbon rich PTFE has better dimensional stability as compared to Pure PTFE. It reduces the material tendency to creep even in the high load. These properties make the product or application maintain its shape and size for a long time.

Applications of Best Carbon Filled PTFE with 25-35% Carbon Filler

The unique properties of Carbon PTFE with 25-35% carbon filler are ideal for use in many industries-

- Automotive Industry: It is employed in seals, gaskets, and bearings for high stress and temperatures. Because they demand high wear resilience.

- Electronics and Electrical Components: It is used in the conductive gasket, anti-static parts and insulation material products. Because it delivers both electrical and thermal conduction.

- Aerospace Industry: It is used in aerospace parts. Because their function calls for high mechanical strength, heat resistance and adhesion to working under undesirable conditions.

- Chemical Processing: PTFE Valve seats, pump parts, liners, where anti-corrosive chemical solutions need to be resisted to avoid degrading of material.

- Industrial Equipment: It is suitable for use in producing bushings, washers, wear strips and other components of the machinery. Because they undergo relatively high wear and friction.

FAQ’s

Why are carbon-filled products considered the best?

Carbon-filled PTFE products are best due to their excellent wear resistance, lower deformation, excellent thermal conductivity, and electrical properties.

Where can we use Carbon Filled Teflon?

Carbon-filled Teflon is commonly used in applications like seals, bearings, bushings, and electrical components.

What percentage of carbon filler did you use in the Carbon-Filled Teflon?

They typically contain 25-35% carbon filler. However, you can also customize your requirements as per your application.

How does carbon affect the properties of PTFE?

The addition of carbon in the PTFE improves the properties. It makes the product more wear-resistant, reduces creep, and increases thermal and electrical conductivity.

Reviews

There are no reviews yet.